| MULTI-BULKHEAD BONDING SYSTEM™-- WHY CALIBER'S DON'T SUFFER FROM STRESS |

| Don't look for a pre-fab fiberglass liner inside a Caliber. Instead, look at how we've integrated dozens of interior members into the hull and deck to take on the stresses of wind and water. |

| The interior of a Caliber is hand-crafted for strength, not mass produced from a glass liner. All our bulkheads are individually taped in place top to bottom throughout the entire hull, bow to stern. Interior components, from the floor stringers and the subsole to bulkheads and shelves, are all solidly hand-laminated to the hull with fiberglass. Such thorough lamination is virtually impossible when installing a one-piece fiberglass liner. Our Multi-Bulkhead Bonding System™ is a painstaking construction method that adds greatly to a Caliber’s durability as interior surfaces double as structural members. Even the settees help the hull carry the loads of the sea. |

|

Multi-Bulkhead Bonding System™ |

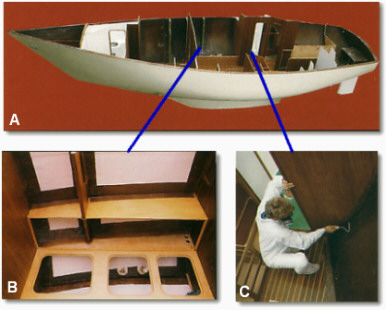

A. No labor saving, fiberglass pans in this method of construction. Everything is bonded bow to stern, from top to bottom. It's labor intensive and creates an extraordinarily strong yacht. B. Note the ease of access to bonding all the surfaces. This bonding evenly spreads out loads throughout large areas making the hull strong. C. Our Multi-Bulkhead Bonding System™ ensures that a Caliber can handle the stresses of the sea. Note the bulkhead is taped top to bottom with no obstructions to interfere. |

| From “Offshore Yachts” by John Rousmaniere |

|

“The

hull must be locally strengthened to withstand loads imposed by the mast

and rigging, the ballast keel, and the rudder (if skeg-mounted or

spade). All these loads must be spread out over an area as large as

practicable. Bulkheads and vertical floors are the best way to

distribute the stresses from ballast weight and mast compression. Bulkheads required by the interior accommodations can do double duty and will contribute greatly to the structural integrity of the hull and deck if they are installed as true structural members rather than simple partitions. Considerable strength is gained this way, at very little expense in weight.” |

| From “The IBEX Report” by Steve Callahan for Cruising World magazine |

|

“All

internal structures-- bulkheads, floors, longitudinals, even furniture,

should be structurally tied together and to the hull wherever feasible.

Rob Schofield, N.A., a composites and structural specialist, says bulkheads and other components that meet the hull must be tabbed in on both sides. “Peel is the big enemy,” he says. “Glass is very strong in tension and compression, but you most easily peel it. Tabbing on one edge alone just doesn’t cut.” |