The power to drive your yacht through the sea also can contribute to

driving you crazy. We designed the 47LRC SEries propulsion system to

help minimize vibration and noise. In an ordinary engine/shaft

installation, the thrust of the propeller drives the shaft forward. In

turn, this puts the direct propeller thrust against the back of the

engine, loading the engine mounts, and in turns, pushes the hull

forwards. With the 47LRC SEries design, we take the power of the thrust,

and stop it before it reaches the engine and engine mounts.

The power to drive your yacht through the sea also can contribute to

driving you crazy. We designed the 47LRC SEries propulsion system to

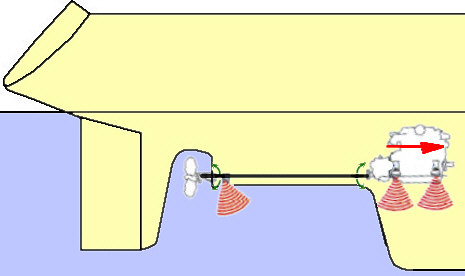

help minimize vibration and noise. In an ordinary engine/shaft

installation, the thrust of the propeller drives the shaft forward. In

turn, this puts the direct propeller thrust against the back of the

engine, loading the engine mounts, and in turns, pushes the hull

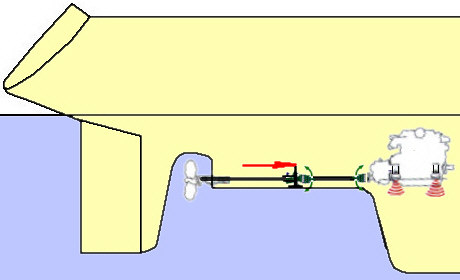

forwards. With the 47LRC SEries design, we take the power of the thrust,

and stop it before it reaches the engine and engine mounts. ad. Which in turn means the engine mounts are free to do what they were designed to do--absorb the vibration of the engine before it reaches the hull. Tests have shown this dramatically reduces the noise and vibration caused by the diesel engine. More comfort to you, less wear and tear on the engine and the mounts. What’s more, this special feature of the 47LRC SEries eliminates the worry about engine alignment as the Aquadrive unit is completely self-aligning.

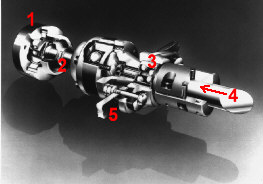

Aquadrive Anti-Vibration System

More Vibration and Noise

Less Vibration and Noise

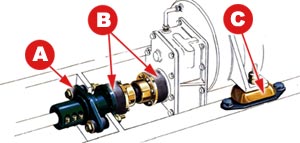

2. Flexible shaft to transfer power to engine so no alignment is ever required.

3. Special bearings purposed designed to bear thrust loads.

4. Propeller thrust load direction.

5. Stainless brackets to transfer loads from engine to load bearing beds.