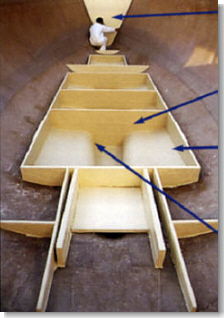

| QUESTION: What is the Integral Strength-Grid System™? | |

| ANSWER: It is a labor-intensive method of construction that is used to bond together all sub-sole components into a strong cohesive unit which forms the backbone of the LRC SEries yachts. The tanks, instead of simply being dropped in place, are heavily laminated within the hull-- Integral FRP Tanks. The combination of lids, baffles, stringers, and even the sub-sole, all interact to form a very rock solid structure to spread primary sea loads over a very large surface area. As an added benefit, the tanks due to their extra strong integrated construction, serve as a double-bottom safety effect. | |

|

Integral Strength-Grid System™ |

|

|

Water-tight Collision Bulkhead heavily glass bonded to the hull and structural dividers forward of it. This creates an extremely strong matrix structure. |

| Integral tanks, lids, baffles add tremendous strength to sub-sole structure to spread loads over hull. Lids are heavily bonded so the tanks create a double-bottom effect. | |

| Structural sub-sole are laminated around its entire perimeter adding a complete bonding between grid structure and hull. | |

| Stringers are heavily glassed into position with extra heavy laminates and resins. Entire grid structure acts as a single strong unit. | |